Industrial Epoxy Flooring

Industrial epoxy flooring is a popular and durable option for commercial and industrial flooring needs. It consists of a resin and hardener mixed together to create a thick, adhesive coating applied to a concrete substrate. Here at Columbus Concrete Contracting, we specialize in industrial epoxy flooring, offering a range of colors, patterns, and finishes to meet the specific needs of our clients. Their epoxy flooring is known for its high quality, resistance to chemicals and abrasions, and easy maintenance, making it an ideal choice for industrial settings.

Industries that Utilize Industrial Epoxy Flooring

Warehousing and Logistics

Epoxy flooring is widely used in the warehousing and logistics industry due to its durability, resistance to wear and tear, and easy maintenance. In these facilities, heavy loads are frequently moved around on pallet jacks, forklifts, and other machinery, which can cause significant damage to the flooring. Industrial epoxy flooring can withstand the weight and impact of these machines without cracking or chipping, reducing the need for costly repairs or replacements. Additionally, epoxy flooring is resistant to chemicals, stains, and spills, making it ideal for facilities where chemicals, oils, and other liquids are frequently used.

Food and Beverage Industry

Epoxy flooring is a popular choice for food and beverage facilities due to its sanitary properties and resistance to bacteria growth. Maintaining a clean and hygienic environment in these facilities is critical to ensuring food safety. Industrial epoxy flooring is seamless, which means it has no cracks or crevices for bacteria to grow, making it easier to clean and sanitize. Additionally, epoxy flooring is resistant to harsh chemicals and acids, making it ideal for areas where food and beverages are processed, such as kitchens, processing areas, and bottling plants.

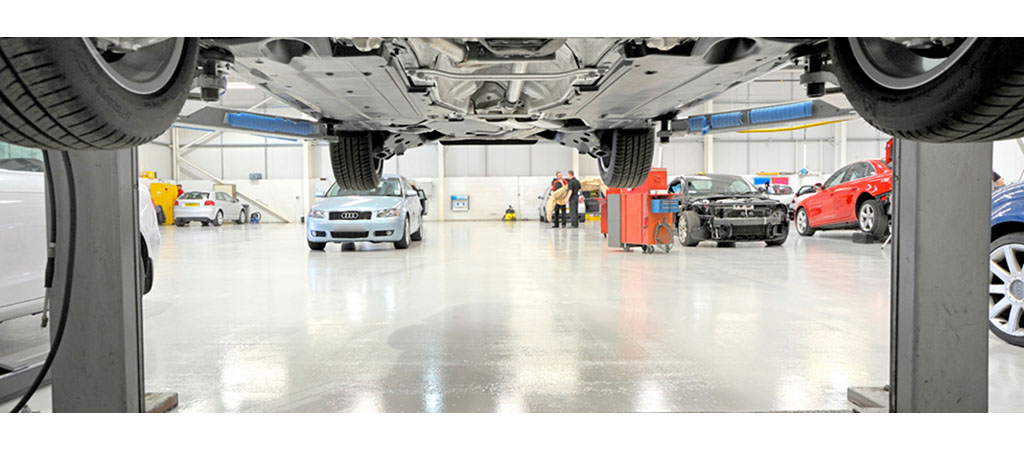

Automotive Industry

Epoxy flooring is a popular choice for the automotive industry due to its resistance to chemicals, oils, and grease, as well as its durability and easy maintenance. In these facilities, chemicals, and oils are frequently used, which can cause significant damage to flooring if not properly protected. Industrial epoxy flooring can withstand these substances without staining or deteriorating, reducing the need for frequent repairs or replacements. Also, epoxy flooring is slip-resistant, making it safer for workers constantly moving around machinery and vehicles.

Learn the Benefits of Industrial Epoxy Flooring

- High durability and resistance to wear and tear

- Resistant to chemicals, oils, grease, and other substances

- Seamless and easy to clean, reducing the risk of bacteria growth

- Can withstand heavy machinery and equipment without cracking or chipping

- Slip-resistant, improving safety in industrial settings

- Available in a range of colors, patterns, and finishes to meet specific needs and aesthetics

- Long-lasting and low maintenance, reducing overall costs

- Eco-friendly options available, such as low VOC and recycled content formulations

- Can improve the overall appearance of an industrial space

- Can enhance the value of a property and attract potential buyers or tenants

Metallic Epoxy Coatings

Metallic epoxy coatings are a type of industrial epoxy flooring that has a unique, eye-catching appearance. These coatings consist of metallic pigments mixed with epoxy resin, which creates a shiny, reflective surface that resembles polished metal. Metallic epoxy coatings are popular in commercial and residential settings, particularly for transforming ordinary concrete floors into visually stunning surfaces. They are available in a range of colors and designs and can be customized to suit any aesthetic preference.

Flake Epoxy Services

Flake epoxy services are a type of industrial epoxy flooring that incorporates colored vinyl chips or flakes into the epoxy resin. These flakes create a multi-colored, textured appearance that can resemble natural stone or granite. Flake epoxy services are commonly used in commercial and residential settings, particularly for their ability to add visual interest and texture to concrete floors. They are available in a range of colors and patterns and can be customized to suit any interior design style. Additionally, flake epoxy services offer the same durability and chemical resistance as traditional epoxy flooring, making them an ideal choice for high-traffic areas requiring a durable and visually appealing surface.

The Basics of Industrial Epoxy Flooring

Care and Maintenance for Industrial Epoxy Flooring

Installation Process for Industrial Epoxy Flooring